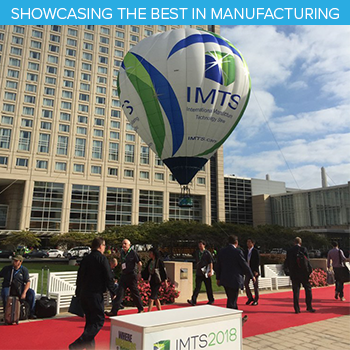

This past month marked the biannual Christmas for manufacturing and engineering professionals, as IMTS once again graced MMI’s own home city of Chicago. All 1,000,000+ square feet of the city’s famed McCormick Place convention center were packed to the brim by a record breaking 2,563 companies, each showing off the latest and greatest in manufacturing technology. On top of that, the show boasted perhaps an even more exciting first… MMI’s very first IMTS booth!

So, whether you just couldn’t make the trip out to Chicago, or you simply couldn’t get to everything featured on the mammoth trade show (to be honest, who could?), MMI’s got the scoop on some of the most exciting stuff we saw at IMTS this year!

3D Printing is Here to Stay

IMTS 2018 was a show too big to steal—but damn if that was going to stop these guys from trying. 3D Printing, also known as additive manufacturing, has made exponential leaps in the past two years, and its top engineers and manufacturers were eager to show off what their new machines are capable of.

The 3D Printing pavilion, massively expanded since that of two years ago, featured a bevy of stunning demonstrations. Many manufacturers focused on the ever growing practical applications of the fledgling technology, showcasing the ways in which 3D printing can be used in the place of—and in tandem with—traditional machining to create parts and prototypes. Other companies, on the other hand, used colorful and intricate recreations of movie and comic book characters to really show off the precision their printers were capable of.

All in all, it was an enlightening display of the capabilities of a field that will no doubt continue to expanding as a mainstay in the manufacturing world.

The Giant Robot Uprising

Robots are no longer the gimmicky draw they once were. While once a stunning beacon of the future, nowadays robots are just another tool on the shop floor, and most manufacturing workers have toiled alongside at least a few in their time. None of this is to say, of course, that robotics can’t still impress. On the contrary, we only mean to say that to keep blowing visitors away, robotics manufacturers will have to keep upping their game, and boy did they deliver.

There was a notable presence from collaborative robots, or cobots, at this year’s show. These robots are designed to be smaller and slower than your typical manufacturing bot, in order to allow them to safely work directly alongside human factory workers. Danish companies Universal Robots and OnRobot both demoed impressive new cobots with a host of new features, such as improved gripping and tool change technology.

But of course, it was good old Fanuc that brought out the showstopper. The M-2000iA lifter, a massive yellow bicep which effortlessly hoisted a minivan 10 feet off the showfloor, absolutely dominated the attention of everyone around it. Sure, your average shop owner’s probably a gonna get a little more out of the cobots, but come on. Who doesn’t want to watch a giant robot?

An Industry Rejuvenated

We already mentioned in the introduction that IMTS has never had this much space or this many booths, but that’s just the tip of the iceberg when it comes to IMTS 2018’s new records. In addition to high company turnout, the final guest tally landed at nearly 130,000 visitors, shattering a 20 year old attendance record by 6%. Many companies pulled out all the stops for 2018 too, with manufacturers like Okuma showing off more machines than ever before.

We’ve written before about how the improving economy has been breathing new life into the manufacturing industry, and nowhere was that more evident than at IMTS 2018. Seeing this tremendous convention center packed with enough people to fill a small city, it was hard not to feel optimistic about the future of manufacturing. The attendance skewing visibly younger than past years painted images bright future for the coming years.

Smart Mills and the Rise of the 5-Axis

As our bread and butter here at MMI, we had to check out the show’s many CNC cutting machines, and they certainly did not disappoint.

We’ve talked before about the 5-axis mill’s shift from a niche or high end machine tool to an all purpose machine shop staple, and this year’s IMTS was an excellent showcase of that transition. Almost all of the heavy hitters of CNC were showing off new 5-axis models, with even Haas Automation, the king of commodity machines, putting far more emphasis on machines like its UMC1000 and GM-2-5AX than its traditional VMCs and HMCs.

Another clear trend was the rise of “smart machining”—machine tools communicating with one another and with the machinists remotely for maximized efficiency. Mazak showcased its new iSMART Factory™ concept, a plant filled with state of the art machines, each one fully digitally integrated, a design which will no doubt be finding its way to high end aerospace plants and the like within the next few years. Okuma, meanwhile, debuted their new Okuma Connect plan, in which they’re able to retroactively connect a full shop of machines together, regardless of age or control.

Whatever your field of choice, this year’s IMTS did not disappoint, with seemingly every branch of manufacturing pulling out all the stops for this year’s show. This truly was a trade show like no other, and we look forward to the next one blowing us away even more.

ABOUT MACHINERY MARKETING INTERNATIONAL:

MMI is a global leader in used machinery transactions. Buyers can easily browse through hundreds of quality used CNC machines online or talk to an experienced account manager to find the perfect match for their needs. Sellers can get value quick through direct purchase, trade-in, or leverage MMI’s vast marketing network to get the top value on their equipment—and whatever the choice, make use of MMI’s worldwide storage, rigging, logistics, and quick appraisal services. Buying or selling, one machine or one hundred,

MMI is the smart way to BUY MACHINERY and SELL MACHINERY.