As most people know, the word “laser” is an acronym for light amplification by stimulated emission of radiation. When this powerful technology is guided and controlled with a multi-axis CNC machine, it can cut and shape different work materials by directing the output of the high-power laser through optics. In a CNC laser cutting machine, motion control system guides are used to direct the material or the laser beam optics. The laser is directed at the material, which then cuts the workpiece, and leaves a high-quality finish. There are three types of industrial laser cutters: CO2, YAG, and Excimeter. CO2 laser cutters are the most common in industrial settings and in this article, we will discuss the 3 most important qualities to look for in one.

CO2 Lasers: In CO2 laser cutters, a laser is produced by running an electric current through a tube, which contains a mix of carbon dioxide, hydrogen, nitrogen and helium, producing a strong light. The tubes contain two mirrors, one which is reflective and the other which allows infrared light to pass. The reflective mirrors serve to excite the nitrogen molecules and build power. On a CNC laser cutter, the laser is moved along its axis and over the work material, cutting the material into the desired piece. The distance between the focal point of the laser and work material is maintained by a height control system, which determines the quality of the cut being made.

What to look for: The three most important qualities to look for when shopping for a CO2 laser are tube quality, bed size, and wattage. The three different qualities will vary based on your business needs, but should be kept in mind, especially if shopping for a used CO2 laser cutter.

-

Tube: As mentioned, the tube is what holds the gas mixture together. These are typically made of glass, metal, or ceramic. Glass tubes are typically the cheapest of the three and will need to be replaced every 500 cutting hours. The max beam diameters that these tubes produce is 5mm, making them better suited for smaller cuts. Metal tubes are more expensive, but a good metal tube will last 3-5 years depending on usage. Their beam diameters usually exceed 2.0mm, making them good for medium size operations. Ceramic tubes are the most expensive of the three, but last up to 6 years and typically have a better power consistency than glass or metal tubes. They are also able to produce beam diameters of over 2.2mm, making them great for large cuts.

-

Bed: While shopping for a laser, know what bed size your manufacturing operation will require. The bigger your work materials, the bigger bed you will need. A bigger bed also allows for more production to be run on a single cut.

-

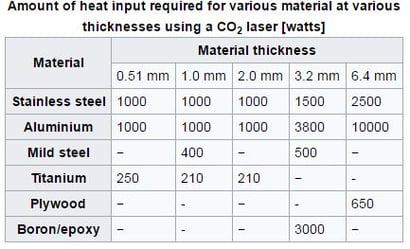

Wattage: Perhaps the most important thing to keep in mind while shopping for a laser is the wattage. The wattage will determine what your laser can and cannot cut. CO2 lasers can generate over 2000 watts, depending on the machine. The higher the watts, the stronger the laser is. As a general rule, 400 watts will be able to cut mild steel. For larger industrial operations, particularly those that shape heavy metals, wattage of over 1000 will be needed. The chart below is a good reference guide for gauging the wattage required for cutting different materials:

Different laser cutters will have different capabilites. Click the button below to compare and contrast laser cutters and find one that fits your business needs.

Different laser cutters will have different capabilites. Click the button below to compare and contrast laser cutters and find one that fits your business needs.