EDM or electrical discharge machining is a manufacturing process by which heated electrodes are utilized to shape a workpiece by melting away excess materials. There are two kinds of EDM machines: wired and sinker. This article will go over the differences between the two machines and their applications.

Sinker EDM: Sinker EDMs work by submerging two connected metal parts, an electrode and workpiece, in an insulated fluid, that when turned on, produces an electric current that shapes the workpiece into the shape of the electrode. This fluid controls and maintains the uniform temperature of the operation. Without it, thermal shock would occur, causing the workpiece to expand and break. Because the shape of the electrode is replicated, sinkers are a good choice for manufacturing dies and molds.

In this historical video, NASA uses Sinker EDMs to create the injectors for the J-2 rocket engine that were used in the Apollo Missions

Wired EDM: In wired EDMs, a heated, hair-thin, electrical wire, usually made from brass, is used to melt away micro-sized particles from work materials to create complex pieces. While cutting is occurring, dielectric liquid or ionized water allows for the eroded debris to be washed away. By utilizing a tiny wire instead of solid cutting pieces, EDM machines are naturally suited for operations that require a super-tight tolerance. The wire, which is spool-fed, is usually held between the upper and lower guides, which move along the x-y axis. The upper guide can usually control movement along multiples axes, which allows the machine to make difficult cuts at complex angles.

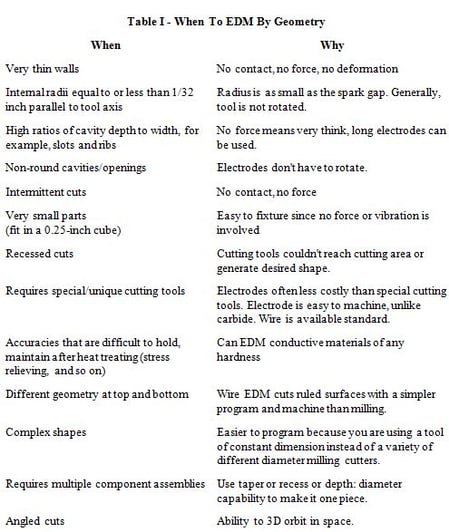

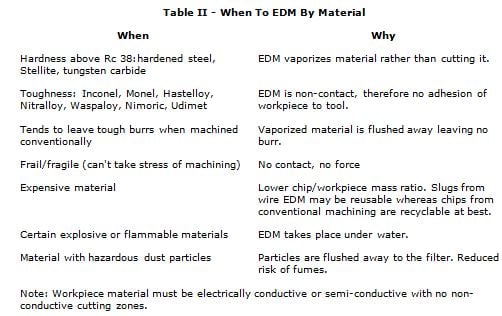

There are many uses for EDM machines. Charmilles Technologies has made a great reference chart that shows when using an EDM is a good choice for your business.

Click the button below and to view and compare our selection of used EDM machines. If you are new to buying used CNC machinery, be sure to download our free comprehensive guide that will answer any questions you may have.