FEBRUARY SAFETY FOCUS: MACHINE GUARDING

Accidents related to improper machine guarding are all too common. In January, OSHA cited Ashley Furniture for dozens of safety violations that carry $1.76 million in fines. Among other violations, OSHA found that the furniture manufacturer did not properly protect workers from being injured by moving parts of machinery. The latest investigation of the furniture company was launched after a tragic incident last July when a worker lost 3 fingers while operating a woodworking machine, and OSHA found that similar machinery had led to 100 other injuries over the last three years.

Learn more: Clothing Safety in the Machine Shop

OSHA standards include 6 general requirements for machine guards that apply to both CNC machines and manual equipment in the machine shop. Saws, presses, and mold-making equipment have additional requirements. The OSHA website has a handy Machine Guarding etool with visuals and examples of each requiremtent below.

In general, all machine guards must:

- Prevent Contact: A good safeguard makes it impossible for workers to get too close to moving parts that could injure them and keeps workers’ hands, arms, and fingers out of danger.

- Be Secure: Guards should be firmly attached to the machine whenever possible. If guards cannot be attached to the machine, they must be secured in such a way that workers cannot remove or bypass the guard.

- Protect from Falling Objects: Safeguards should prevent chips or other debris from falling into or onto moving parts.

- Create No New Hazards: A hand guard with sharp edges or a foot guard that could cause tripping kind of defeats the point. Guards shouldn’t solve one problem by causing another.

- Create No Interference: Workers might try to bypass something that makes it harder for them to do their jobs. Consider the role of the operator when designing guards.

- Allow Safe Lubrication: If possible, guards should allow for workers to add oil or lubricant without entering or reaching into the danger zone. Locate oil reservoirs outside the guard, and add a line to the lubrication point if necessary.

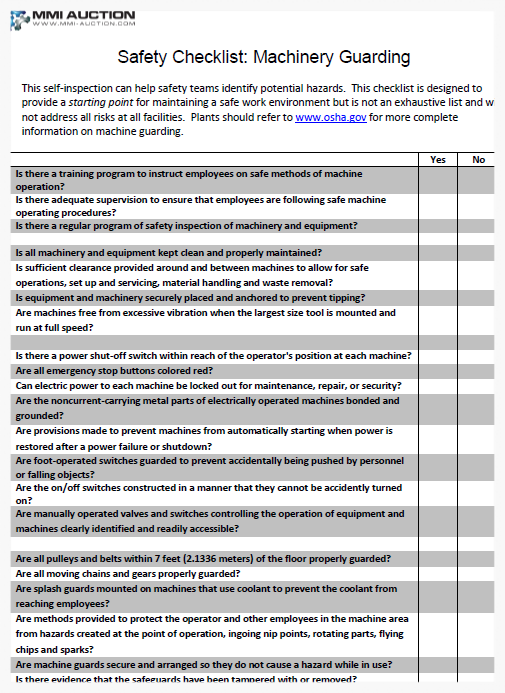

Machine Guarding Checklist

Click the link below to download a printable 28-item checklist you can use to conduct a safety self-inspection at your facility. This general checklist has been written for shops using either manual or CNC machines, but it does not cover the additional OSHA standards that apply to saws, presses, or mold-making equipment. Please visit www.osha.gov for more information on those requirements.

We hope this information can provide a starting point for safety teams, but it won’t cover all risks at all facilities. Managers should visit www.osha.gov for complete regulations, additional resources, and tools for starting a safety program.

OSHA has a free guide for small businesses that can be printed or viewed online.

Stay safe!