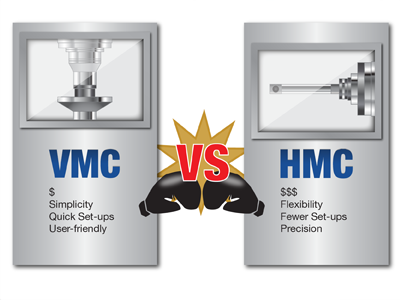

Your machine shop is ready to expand. Wonderful! Should you add another vertical machining center or make the investment in a horizontal?

To answer that question, you will need to take a good look at where your shop is today and where you hope to go with the acquisition of a new machine. Think about the customers you have now and the customers you want in the future. Consider what you really need the machine to do in terms of production goals, accuracy, and flexibility. When it comes to finances, make sure you factor in all the costs outside of the initial machine purchase, including things like tools, software, training, maintenance, and repairs.

Sound overwhelming? The good news is that there's a wealth of information available online to help with your decision. Here we offer a few considerations to get you started, as well as links to in-depth sources for more information.

1. Cost and Cash Flow

Let’s face it: the sticker shock on a new horizontal machining center (HMC) can be overwhelming, and shops need to make additional investments in computers, software, tool management systems and inspection equipment to get the maximum return on investment. Long-term productivity gains offset these additional costs, but careful cash flow management is crucial in the implementation stage. For a detailed list of the costs and benefits of horizontal machining, scroll to the bottom of this article.

Many shops lower their initial costs by seeking out high-quality used horizontal machining centers through private sales and online CNC auctions. A good machinery broker can serve as your eyes and ears in this marketplace, and a few, including MMI, will guarantee the equipment as well.

Alternately, a vertical machining center (VMC) costs about half as much as an HMC, and a shop adding one additional VMC will be able to use their existing technology and tools with the new machine. When capital is tight or cash flows are sluggish, a VMC is probably the best choice.

2. Customers

In general, VMCs have faster setups, so a shop with many small customers placing small volume parts orders (or a shop that frequently bids on prototype work) will be able to change to the next job more quickly. These machines are also the best choice for large plate work. Read more about technical considerations when buying a VMC here.

HMCs have fewer setups, and can also tool multiple parts at the same time. The rotating palettes mean the machine never sits idle. Programming is complicated and setup takes longer, but complex parts can be produced quickly and accurately. Shops bidding on long runs or complex parts will see the biggest gains from an HMC.

3. Labor

VMCs are more common in machine shops, so operators and programmers are more likely to be familiar with the controls. For work requiring a high level of precision, experienced machinists will need to perform each setup. Shops in regions with a history of manufacturing and a skilled or semi-skilled workforce will be able to reap the most benefits from a VMC.

A shop purchasing its first HMC will almost certainly need to invest in training to maximize the return on the machine, since they are harder to use and fewer workers have experience with them. Programmers must be very highly skilled, however, the machine needs little input from operators once it starts running. Since a single HMC can often do the work of 2 or more VMCs, a shop may need fewer staff members overall.

MMI has both horizontal and vertical machining centers in stock, and more are added every week. Visit MMI-Auction.com for our latest machining centers in our online auctions. To view our complete inventory, visit MMI-Direct.com.

Have an idea of the CNC machine you’re looking to add to your shop? Click the button below, then scroll down to fill out our Find a Machine Form.